Exploring the Best Heat Sealing Machines: Features, Applications, and Usage Tips

In today's fast-paced manufacturing and packaging industries, the efficiency and reliability of heat sealing machines play a crucial role in ensuring product integrity and customer satisfaction. According to a recent market report by Research and Markets, the global heat sealing machine market was valued at approximately $870 million in 2020 and is projected to reach $1.2 billion by 2026, driven by the growing demand for food packaging, pharmaceutical packaging, and industrial applications. These machines utilize heat to create airtight seals, which not only extend the shelf life of products but also improve packaging aesthetics. As companies strive to enhance their productivity and reduce waste, understanding the features, applications, and best practices for using heat sealing machines becomes essential for success in a competitive landscape. This blog will guide you through the various aspects of heat sealing machines, helping you make informed decisions for your business needs.

Understanding Heat Sealing Machines: Key Features and Benefits

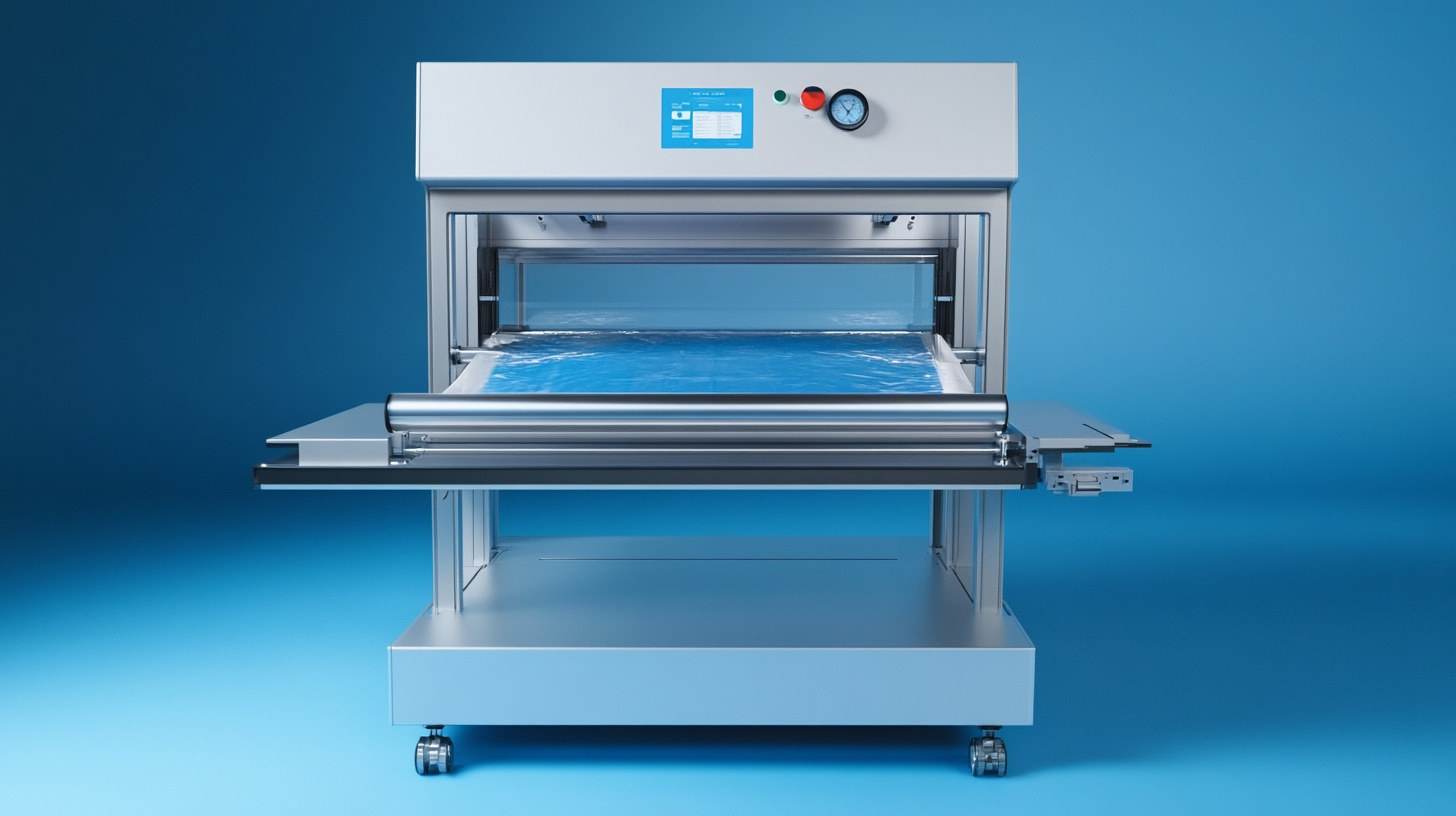

Heat sealing machines are essential tools in various industries, offering both efficiency and reliability when it comes to packaging. The key features of these machines include adjustable temperature controls, sealing speed settings, and various sealing modes that cater to different materials. For example, impulse sealers create a seal by applying heat only for a short duration, while continuous sealers maintain a steady sealing process. These features not only enhance performance but also allow businesses to customize their packaging processes based on the product's needs.

Heat sealing machines are essential tools in various industries, offering both efficiency and reliability when it comes to packaging. The key features of these machines include adjustable temperature controls, sealing speed settings, and various sealing modes that cater to different materials. For example, impulse sealers create a seal by applying heat only for a short duration, while continuous sealers maintain a steady sealing process. These features not only enhance performance but also allow businesses to customize their packaging processes based on the product's needs.

The benefits of using heat sealing machines extend beyond mere efficiency. They offer a secure and tamper-proof seal, ensuring product integrity and safety during transport and storage. Additionally, the machines are versatile, suitable for sealing a wide range of materials such as plastics, aluminum foils, and laminated films. This flexibility makes them ideal for various applications, from food packaging to electronics. By investing in a quality heat sealing machine, businesses can improve their packaging operations, reduce waste, and ultimately enhance customer satisfaction through better-preserved products.

Common Applications for Heat Sealing Machines Across Various Industries

Heat sealing machines are pivotal in numerous industries, with applications ranging from packaging and food preservation to medical supplies and electronics. According to a report by Research and Markets, the global heat sealing machines market is expected to reach USD 1.45 billion by 2025, growing at a CAGR of 5.1%. This growth is driven by the increasing demand for efficient packaging solutions that extend product shelf life while minimizing waste.

In the food industry, heat sealing is essential for maintaining the freshness of products and ensuring safety standards. The packaging process helps prevent contamination and extends shelf life, making it particularly popular for perishable items. For instance, the 2020 Food Packaging Technology report indicates that over 80% of food products are packaged using heat sealing techniques.

On the healthcare front, heat sealing machines are critical for sterilizing and packaging medical products, with a projected market size of USD 800 million by 2023, according to industry analysts. This trend emphasizes the importance of reliable sealing technology in maintaining the sterility of instruments and supplies.

As heat sealing technology advances, its applications continue to expand, providing diverse industries with innovative solutions that enhance productivity and product quality. With ongoing developments, businesses can expect even more efficient and sustainable options for their packaging needs in the years to come.

Top Types of Heat Sealing Machines: A Comparative Overview

When it comes to selecting a heat sealing machine, understanding the different types available can make all the difference in achieving the best results for your specific needs. There are several categories of heat sealing machines tailored for various applications, from handheld models ideal for small food storage tasks to more robust commercial-grade machines designed for high-volume production. Each type brings unique features that cater to distinct packaging requirements, making it crucial to evaluate them based on your sealing demands.

In the realm of food packaging, heat sealing technology plays a vital role in extending shelf life and maintaining freshness. It’s important to note that the integrity of the seal can be influenced by multiple factors such as temperature, time, and pressure applied during the sealing process. Knowing how these elements affect seal quality can help you choose a machine that provides reliable performance, whether you’re packaging delicate produce or heavy-duty items. By comparing various heat sealing machines and understanding their applications, you can ensure optimal preservation of your food products while minimizing waste.

Exploring the Best Heat Sealing Machines: A Comparative Overview

Essential Usage Tips for Optimal Performance of Heat Sealing Machines

When utilizing heat sealing machines, achieving optimal performance is crucial for efficiency and quality in packaging processes. One essential tip is to maintain the proper temperature settings. Each material has a specific temperature range for effective sealing, so it's important to consult the material guidelines. Conducting test seals before large production runs can help identify the best settings, preventing issues like under-sealing or burnt edges.

Another vital aspect is the preparation of the materials being sealed. Ensure that the surfaces of the items to be sealed are clean and free from contaminants such as dust, oil, or moisture, as these can hinder adhesion. Additionally, proper alignment of materials is key; misalignment can result in weak seals and increased waste. Regular maintenance, including cleaning and inspecting the sealing elements, can significantly improve the longevity and performance of the machine, ultimately leading to better results in your sealing operations.

Exploring the Best Heat Sealing Machines: Features, Applications, and Usage Tips

| Machine Type | Max Seal Width | Seal Thickness | Power (Watts) | Applications | Usage Tips |

|---|---|---|---|---|---|

| Impulse Sealers | 12 inches | 6 mil | 300 | Plastic bags, Mylar bags | Ensure proper pressure; adjust heat time accordingly. |

| Continuous Band Sealers | 16 inches | 12 mil | 500 | Food packaging, electronics | Maintain consistent speed; clean sealing area regularly. |

| Vacuum Sealers | 10 inches | 8 mil | 200 | Meat, vegetables, and liquids | Pre-freeze liquids; ensure proper bag size. |

| Handheld Sealers | 4 inches | 2 mil | 100 | Small packages, travel bags | Use steady pressure; seal only dry items. |

Navigating Industry Certifications and Standards for Heat Sealers

When selecting a heat sealing machine, understanding industry certifications and standards is crucial for ensuring reliable performance and safety. Different organizations, such as the International Organization for Standardization (ISO) and Underwriters Laboratories (UL), set specific standards that heat sealers must meet. These certifications not only signify the quality and safety of the equipment but also provide assurance that the machine has been rigorously tested to operate at optimal efficiency within its intended applications.

For instance, a heat sealer with ISO certification guarantees conformity to international quality benchmarks, which can be particularly important for businesses involved in food packaging or pharmaceuticals. Compliance with these industry standards ensures that the sealing process will not compromise product integrity or safety, thereby protecting both the consumer and the brand reputation. It's essential to choose heat sealing machines that carry recognized certifications, as this choice aligns with best practices in manufacturing and packaging processes. Remember to verify the certifications specific to your industry to ensure that the heat sealing equipment you choose adheres to the necessary guidelines for optimal results.