Unveiling the Challenges: Common Issues with the Best Heat Sealing Machines

In the world of packaging, the heat sealing machine stands out as an essential tool that ensures product integrity and extends shelf life. However, despite their critical role in various industries, these machines often come with their own set of challenges. From inconsistent sealing quality to mechanical failures, the issues associated with heat sealing machines can significantly impact production efficiency and output. As global manufacturers continue to strive for excellence, understanding these common problems becomes paramount. This blog aims to unveil the challenges faced by businesses when using heat sealing machines, shedding light on the necessary precautions and solutions to optimize their performance. With "world-class manufacturing, China's pride, exporting globally" as the backdrop, we will explore how addressing these obstacles can lead to enhanced productivity and competitiveness in the international market.

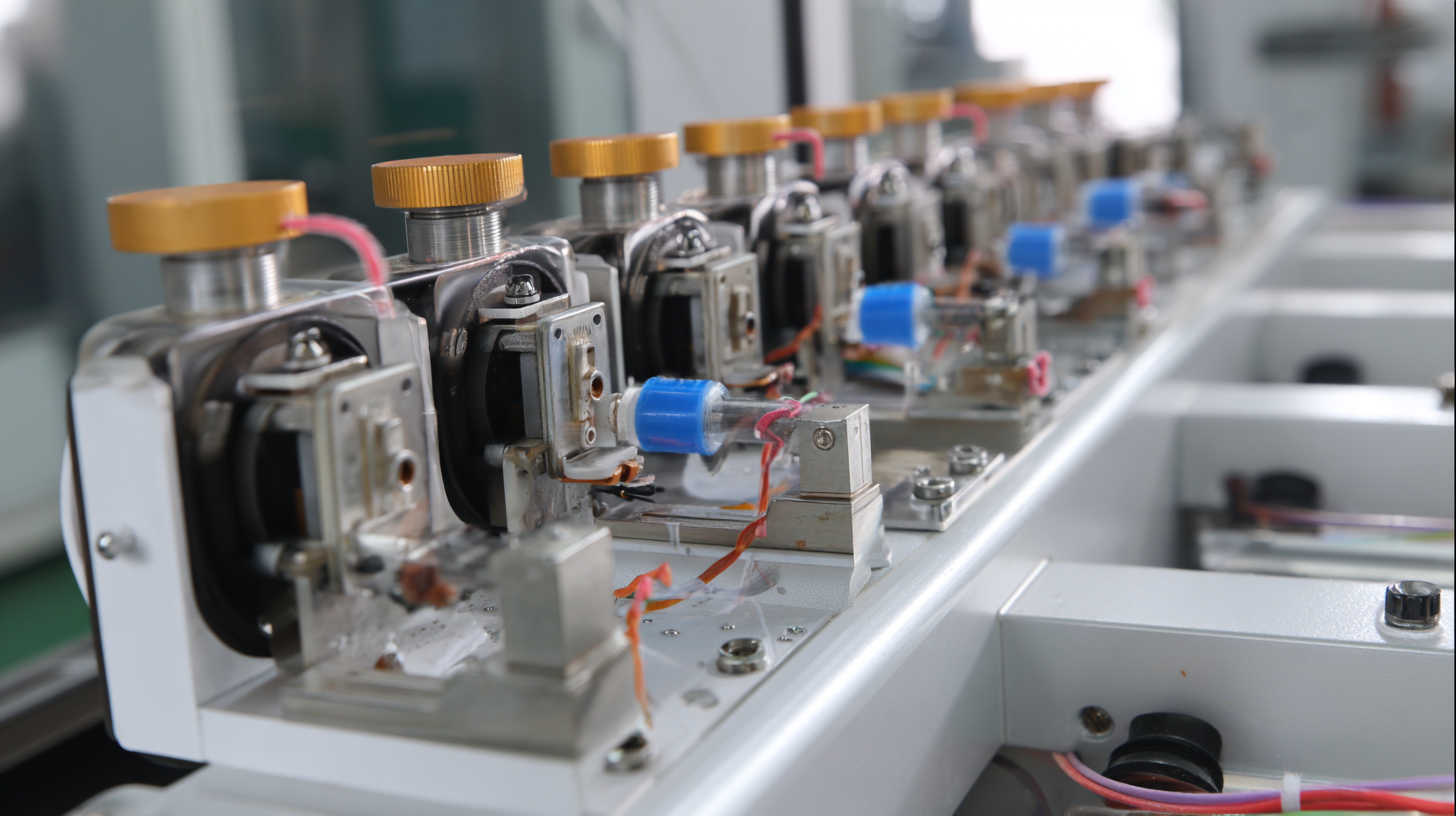

Understanding the Importance of Quality in Heat Sealing Machines for Optimal Performance

When it comes to the performance of heat sealing machines, quality cannot be overlooked. High-quality machines ensure a consistent seal, minimize product spoilage, and enhance overall production efficiency. Poorly built machines may lead to leaks, product damage, and increased downtime, ultimately affecting your bottom line. Therefore, investing in a well-constructed heat sealing machine is essential for maintaining product integrity and meeting industry standards.

Tip: Always check for certifications and user reviews when selecting a heat sealing machine to guarantee you're buying a reliable product. It helps to choose brands that provide solid warranties and customer support.

Moreover, regular maintenance and proper operation techniques significantly influence the performance of heat sealing machines. Operators should be trained to set appropriate temperature and pressure settings for different materials. Neglecting these factors could result in poor seals or machine malfunction.

Tip: Schedule routine checks of seals and machine performance to catch potential issues before they escalate. Implementing a preventive maintenance schedule can extend the life of your equipment and improve production reliability.

Common Operational Issues in Heat Sealing: Insights from Industry Experts

Heat sealing machines are essential tools in various industries, yet they often come with a set of operational challenges that can hinder their efficiency. One of the most common issues reported by industry experts is inconsistent sealing quality. This inconsistency can arise from various factors, including incorrect temperature settings, insufficient pressure, or improper material alignment. Ensuring that machines are calibrated correctly and regularly maintained can significantly mitigate these problems, leading to improved productivity and reduced waste.

Another frequent operational issue stems from the use of incompatible materials. While heat sealing machines are designed for a range of materials, using the wrong type can result in bonding failures or compromised seal integrity. Experts advise conducting thorough compatibility tests before commencing large-scale production. Additionally, training staff on the specific requirements of different materials can help avert potential pitfalls, ensuring that production processes run smoothly and efficiently. By addressing these common operational issues, businesses can enhance their heat sealing operations and achieve better overall outcomes.

Unveiling the Challenges: Common Issues with the Best Heat Sealing Machines

| Issue Type | Description | Frequency of Occurrence | Impact on Production | Expert Recommendation |

|---|---|---|---|---|

| Incorrect Temperature Settings | Inconsistent sealing quality due to improper temperature. | High | May lead to product spoilage or waste. | Regular calibration and training on settings. |

| Material Compatibility | Certain materials may not seal effectively. | Medium | Can result in inadequate sealing and product leaks. | Test materials before large-scale production. |

| Pressure Issues | Inadequate pressure leading to poor seals. | Medium | Increases chances of product failure in the market. | Ensure proper pressure calibration frequently. |

| Operator Error | Mistakes made during setup or operation of machines. | High | Can cause major disruptions and increased downtime. | Comprehensive training sessions for operators. |

| Maintenance Issues | Neglect in routine maintenance causing malfunctions. | High | Leads to unexpected downtimes and repair costs. | Implement regular maintenance schedules. |

Analyzing the Impact of Material Compatibility on Heat Sealing Efficiency

Heat sealing is a crucial process in packaging, especially within the food industry, where material compatibility significantly affects sealing efficiency. Recent studies have highlighted the importance of selecting the right materials for heat sealing applications to ensure the integrity and longevity of packages. For example, using flexible packaging materials that are chemically compatible can prevent issues such as seal failures and contamination. These failures often occur due to inadequate heat transfer or undesirable chemical interactions between the material layers.

To enhance heat sealing efficiency, consider the following tips:

- Always verify the compatibility of your sealing materials. Conduct tests on sample seals to assess their integrity under different temperatures and environments.

- Maintain precise control over the heat sealing parameters, such as temperature, pressure, and time, to achieve optimal results.

- Explore the use of advanced materials designed to enhance thermal properties, as recent innovations in this field suggest that utilizing specialized materials can lead to improved seal quality and sustainability.

An additional focus should be placed on the environmental impact of sealing materials. The shift towards sustainable practices includes the exploration of waste-based materials which not only reduce environmental footprints but can also perform effectively in heat sealing applications. By prioritizing both material compatibility and sustainability, industries can improve their packaging processes while mitigating ecological harm.

Technological Advancements: Addressing Reliability Challenges in Heat Sealing Machines

The heat sealing machine industry is witnessing significant technological advancements aimed at addressing reliability challenges, particularly in the flexible food packaging sector. With a rising demand for packaged food, the market for tray sealing machines is poised for substantial growth. Studies indicate that improper sealing can compromise the integrity of food packaging, leading to spoilage and food waste—a concern that has prompted manufacturers to prioritize improvements in seal integrity mechanisms. By incorporating more robust materials and precise temperature controls, these machines aim to enhance performance and reliability, ensuring that food stays fresh for longer periods.

**Tip:** When selecting a heat sealing machine, consider models that offer adjustable temperature settings and industry-tested sealing pressures to optimize seal quality for various materials.

Another challenge in the sector is the rapid technological changes, necessitating ongoing upgrades in heat sealing processes and machinery. As the market evolves, understanding material compatibility becomes critical to maintaining seal efficacy. Recent reviews highlight that factors like ambient temperature and humidity can significantly affect seal quality. Manufacturers are advised to conduct thorough testing under different environmental conditions to ensure reliability in their sealing processes.

**Tip:** Regularly calibrate and maintain heat sealing machines to adapt to changing production environments, which can help in sustaining high standards of seal reliability.

Evaluating Maintenance Practices to Prevent Common Heat Sealing Problems

In the world of packaging, heat sealing machines are indispensable for ensuring product integrity and extending shelf life. However, these machines are not without their challenges. Common issues, such as inconsistent seals, faulty temperature regulation, and inadequate pressure application, can arise, often leading to product spoilage and increased production costs. Therefore, understanding and implementing effective maintenance practices is crucial for preventing these problems.

Regular maintenance routines should focus on critical components of heat sealing machines. This includes cleaning heating elements to remove residue that may interfere with temperature consistency and replacing worn-out seals that can lead to improper sealing. Additionally, operators should conduct periodic inspections to check alignment and functionality, ensuring that machines are calibrated correctly. By prioritizing these maintenance practices, businesses can mitigate common heat sealing issues, enhance machine longevity, and ultimately improve overall efficiency in packaging operations.