Why Choose Sandblast Rubber Hose for Your Projects?

When it comes to choosing materials for tough projects, the right tools matter significantly. Andrew Johnson, a leading expert in industrial hoses, once stated, "The quality of your hose affects your project’s success." This highlights the importance of selecting the best products for the job.

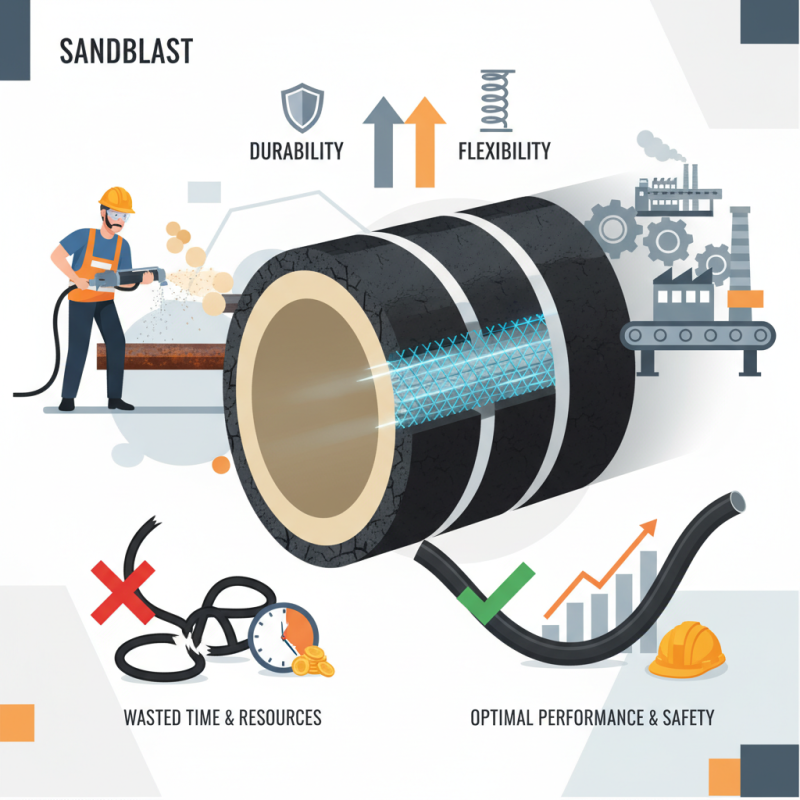

Sandblast rubber hoses are well-known for their durability and flexibility. Professionals in construction and manufacturing often rely on them for effective sandblasting tasks. These hoses can withstand high-pressure conditions, ensuring safety and efficiency on the job site.

However, some users may underestimate their benefits. Choosing the wrong hose can lead to complications. A failure in your equipment could stall progress, wasting time and resources. Thus, investing in a high-quality Sandblast rubber hose is crucial for optimal performance. Consider your needs carefully before making a selection.

Benefits of Sandblast Rubber Hose in Industrial Applications

Sandblast rubber hoses are essential in various industrial applications. They offer unique advantages, particularly in abrasive environments. According to industry data, these hoses can handle high pressures, making them ideal for sandblasting processes. Their robust construction withstands harsh conditions, ensuring reliability.

One significant benefit is flexibility. These hoses can easily navigate tight spaces, which enhances operational efficiency. They are resistant to wear, reducing the frequency of replacements. A report from the Rubber Manufacturers Association indicates that using high-quality sandblast hoses can decrease downtime by up to 25%. However, workers sometimes overlook proper maintenance, which can lead to failure.

Additionally, safety is a priority. Sandblast rubber hoses are designed to minimize the risk of accidents. Their ability to contain abrasive materials safely reduces hazards in the workplace. Yet, improper handling can result in dangerous situations. Regular training and awareness are critical. It’s vital to continually evaluate safety protocols to ensure the effectiveness of these hoses in industrial settings.

Key Features of Sandblast Rubber Hose for Enhanced Performance

When selecting materials for sandblasting projects, the sandblast rubber hose stands out for several reasons. One key feature is its durability. Made to handle high-pressure applications, this hose resists wear and tear exceptionally well. Its robust construction ensures it can withstand the harsh conditions of sandblasting, prolonging its lifespan.

Additionally, the flexibility of the sandblast rubber hose makes it easy to maneuver during projects. It bends easily without cracking, allowing for precise application in tight spaces. This adaptability is crucial for effective performance, but it also means that the hose requires careful handling. If not properly stored, it can develop kinks or become damaged over time. The right maintenance is essential to ensure it remains in top condition.

The reinforced design of the hose enhances its ability to withstand abrasive materials. This feature is vital, yet it demands regular inspection to avoid potential failures. Users should remain vigilant for signs of wear, as even small cracks can lead to larger issues. Balancing performance and maintenance is crucial for optimizing the sandblast rubber hose's effectiveness.

Comparison of Sandblast Rubber Hose with Other Hose Types

When selecting a hose for sandblasting, understanding the material is crucial. Sandblast rubber hose is designed to handle high-pressure and abrasive materials. In contrast, standard rubber hoses may not withstand the harsh conditions of sandblasting. Reports indicate that sandblast hoses can endure pressures up to 150 PSI, while most other hoses fail at lower limits. This significant disparity highlights the importance of choosing the right hose for specific applications.

Many industries use various types of hoses, including PVC and polyurethane. However, data shows that these materials often degrade faster under abrasive conditions. For example, a PVC hose may last only a few weeks in a sandblasting environment. Sandblast rubber hoses, on the other hand, can last for several months, reducing replacement costs. Yet, they are heavier and less flexible than some alternatives. This trade-off must be considered when planning projects.

In terms of safety, sandblast hoses come with built-in protective layers that help prevent abrasions and ruptures. However, not all products on the market meet the safety standards. Some hoses may lack adequate reinforcement, posing risks during operation. Using inferior hoses can lead to accidents, making it essential to choose quality over cost. Overall, while sandblast rubber hose offers superior performance, the balance between durability and practicality is key in project planning.

Why Choose Sandblast Rubber Hose for Your Projects? - Comparison of Sandblast Rubber Hose with Other Hose Types

| Hose Type | Material | Working Pressure (psi) | Temperature Range (°F) | Best Use | Weight (lbs/ft) |

|---|---|---|---|---|---|

| Sandblast Rubber Hose | Rubber | 150 | -20 to 150 | Sandblasting, Abrasive Materials | 2.8 |

| PVC Hose | PVC | 100 | 32 to 140 | General Purpose, Water | 1.5 |

| Air Hose | Rubber/Polymer | 125 | -40 to 200 | Compressed Air, Pneumatic Tools | 2.0 |

| Garden Hose | Vinyl/Rubber | 50 | 32 to 120 | Watering, Gardening | 1.2 |

Maintenance Tips for Extending the Life of Sandblast Rubber Hose

Maintaining sandblast rubber hoses is crucial for ensuring their longevity and effectiveness. Regular inspection is important. Check for signs of wear or cracks. If you find damage, replace the hose immediately. Ignoring small issues can lead to bigger problems.

Proper storage also extends the life of these hoses. Keep them in a cool, dry place. Avoid placing heavy objects on top of them. This can cause unnecessary pressure and lead to failure.

Lastly, cleaning after use is essential. Rinse the hose thoroughly to remove any abrasive materials. Failure to do this can cause blockages and reduce efficiency. Remember, frequent maintenance is often overlooked but it saves time and money in the long run.

Sandblast Rubber Hose: Performance vs. Maintenance Over 12 Months

This chart illustrates the relationship between the performance rating of sandblast rubber hoses and the frequency of maintenance activities over a 12-month period. Regular maintenance appears to correlate with higher performance ratings, demonstrating the importance of proper care to extend the lifespan of the hoses.

Common Uses of Sandblast Rubber Hose in Various Industries

Sandblast rubber hoses are essential in various industries. Their unique design allows them to withstand high-pressure applications. These hoses are widely used in construction, manufacturing, and automotive fields.

In construction, sandblast hoses help with surface preparation. They efficiently remove old paint or rust. This process is crucial for creating a clean and smooth surface. However, users must be careful. Improper handling can lead to damage or accidents. Always check the hose for wear before use.

In the manufacturing industry, these hoses are vital for finishing products. They are often utilized in sandblasting machines. This technique helps in achieving precise surface texture. A common mistake is failing to match the hose size with the equipment. This can result in reduced efficiency and increased wear.

Tip: Regular maintenance can extend the life of sandblast hoses. Store them in a cool, dry place to prevent deterioration. Another tip is to train operators thoroughly. They should understand the equipment and safety measures.