Mastering the Art of Choosing the Right Filling Machines: A Comprehensive Tutorial for Beginners

In today's fast-paced manufacturing industry, choosing the right filling machines is crucial for ensuring efficient production processes and maintaining product quality. Whether you are a small business owner or a production manager at a larger facility, navigating the myriad of options available can be overwhelming. This comprehensive tutorial is designed specifically for beginners, providing a detailed exploration of the various types of filling machines available on the market. From understanding the basic functionalities to identifying the specific needs of your operation, this guide aims to equip you with the knowledge necessary to make informed decisions. Join us as we delve into the essential factors that influence your choice of filling machines, ensuring that you master the art of selecting the right equipment for your filling requirements.

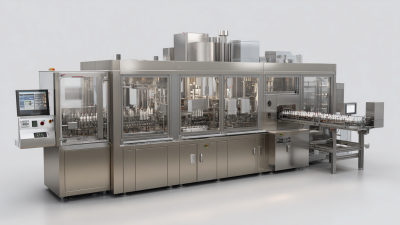

Understanding Different Types of Filling Machines and Their Applications

When it comes to selecting the right filling machine for your production line, understanding the various types available is essential. There are primarily three categories of filling machines: volumetric, gravimetric, and time-based fillers. Volumetric fillers measure precise volumes of product and are ideal for liquids of similar viscosities, ensuring consistency in each package. Gravimetric fillers, on the other hand, weigh the product before filling, making them suitable for varying densities, particularly in dry and granular applications. Lastly, time-based fillers dispense product based on a set time interval, effective for thin liquids but less precise than the other two types.

Each type of filling machine serves different applications, underscoring the importance of assessing your specific needs. For instance, if your product is a viscous sauce, a piston filler, which falls under the volumetric category, would be ideal. Conversely, a dry powder or small granules might require a gravity filler that suits its flow characteristics. By aligning your choice of filling machine with the nature of your product and production goals, you'll optimize efficiency and maintain quality, setting the stage for a successful operation.

Understanding Different Types of Filling Machines

This chart illustrates the various types of filling machines and their respective applications in the industry, highlighting the most common machines used in liquid, powder, and granule packaging.

Key Factors to Consider When Selecting a Filling Machine for Your Business

When selecting the right filling machine for your business, several key factors must be taken into account to ensure efficiency and compatibility with your production needs. According to a recent report by MarketsandMarkets, the global filling machine market is projected to grow from $2.5 billion in 2021 to $3.8 billion by 2026, highlighting the increasing importance of selecting the right equipment. First and foremost, consider the type of product you’ll be filling—viscous, powdery, or liquid. For instance, different filling machines, such as piston fillers for viscous liquids or auger fillers for powders, offer distinct advantages tailored to specific products.

Another critical factor is the machine's production capacity. According to a study published by Research and Markets, the demand for high-speed filling machines is on the rise, driven by the need for increased efficiency and reduced production time. Businesses should assess their expected output and ensure that the chosen filling machine aligns with their manufacturing goals. Additionally, factors such as ease of cleaning, maintenance requirements, and the machine's adaptability to new products should not be overlooked, as these can significantly impact long-term operational efficiency and costs.

Step-by-Step Guide to Evaluating Filling Machine Efficiency and Quality

When selecting the right filling machine, understanding efficiency and quality is paramount. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), efficient filling machines can lead to a 20-30% increase in production rates, significantly impacting overall profitability. Evaluating the speed of the machine, its compatibility with various container types, and setup time are critical components in this assessment.

One tip for beginners is to thoroughly analyze the machine's productivity metrics—such as fill rate and downtime—against industry benchmarks. For instance, a well-optimized filling line typically achieves overall equipment effectiveness (OEE) rates of 85% or higher. Pay attention to the filling accuracy as well; machines that ensure fill weight precision can reduce product wastage, thereby improving quality and reducing costs.

Another crucial factor is the technological advancements integrated into modern machines. Automated systems offer enhanced monitoring and reporting capabilities, allowing for real-time adjustments and ensuring consistent quality. Incorporating machines with predictive maintenance features can also minimize unexpected failures, ultimately leading to more efficient operations. By focusing on these aspects, beginners can make well-informed decisions that enhance both the efficiency and quality of their filling processes.

Mastering the Art of Choosing the Right Filling Machines: A Comprehensive Tutorial for Beginners

| Machine Type | Filling Method | Production Speed (Bottles/Min) | Accuracy (%) | Maintenance Frequency (Months) | Typical Applications |

|---|---|---|---|---|---|

| Volumetric Filler | Piston Filling | 20 | 98 | 6 | Liquids, Sauces |

| Gravity Filler | Gravity Filling | 15 | 95 | 12 | Water, Juice, Wine |

| Aseptic Filler | Aseptic Filling | 25 | 99 | 8 | Dairy, Juices |

| Servo Pump Filler | Pump Filling | 30 | 99.5 | 4 | Cosmetics, Chemicals |

| Fume Filler | Vacuum Filling | 18 | 96 | 5 | Flammable Liquids, Hazardous Materials |

Maintenance Tips to Ensure Longevity and Performance of Filling Machines

When it comes to operating filling machines, consistent maintenance is the key to ensuring their longevity and optimal performance. Regular cleaning is fundamental; any residue left behind can jeopardize the filling accuracy and lead to contamination. It's essential to create a routine cleaning schedule, particularly after shifts or when switching between different products, to maintain hygiene standards and prevent cross-contamination.

In addition to cleaning, regular inspections of critical components such as nozzles, pumps, and sensors can avert unforeseen malfunctions. Checking for wear and tear allows operators to make necessary adjustments or replacements before they impact production. Lubricating moving parts also reduces friction and prolongs the lifespan of the machine. Lastly, keeping an eye on software updates and calibrating the machine periodically ensures that it runs smoothly and efficiently, aligning with the latest operational standards. Proper attention to maintenance not only enhances the performance of filling machines but also significantly reduces downtime and repair costs.

Common Mistakes to Avoid When Choosing a Filling Machine for Beginners

Choosing the right filling machine can be a daunting task for beginners, but avoiding common mistakes can make the process much easier. One of the most prevalent pitfalls is failing to assess your specific needs.

Whether you're filling liquids, powders, or granules, understanding the characteristics of your products is crucial. For instance, if you work with viscous liquids, opting for a gravity filler may not yield the best results.

Another mistake is overlooking the importance of machine compatibility with your production capacity. Many beginners underestimate the volume they need to process, leading to the purchase of a machine that either can't keep up or is overkill for their requirements.

It's vital to evaluate your current and future production needs to ensure your choice aligns with growth expectations.

Tip: Always conduct thorough research on various filling machines and their capabilities. Consider reaching out to manufacturers for demos or trial periods. This hands-on experience can highlight not only the machine's usability but also its efficiency in meeting your demands without compromising on quality.

Related Posts

-

Analyzing the Market Potential for Best Filling Machines in 2025 and Beyond

-

Understanding the Challenges of Filling Machines in Global Supply Chains

-

Exploring the Future of Filling Machines in 2025 Innovations and Implementation Strategies

-

Mastering the Art of Filling Machines A Comprehensive Guide for Beginners

-

How to Choose the Best Filling Machines for Your Business Needs

-

Comprehensive Insights into Heat Sealing Machines for Global Procurement Strategies