Exploring the Future of Filling Machines in 2025 Innovations and Implementation Strategies

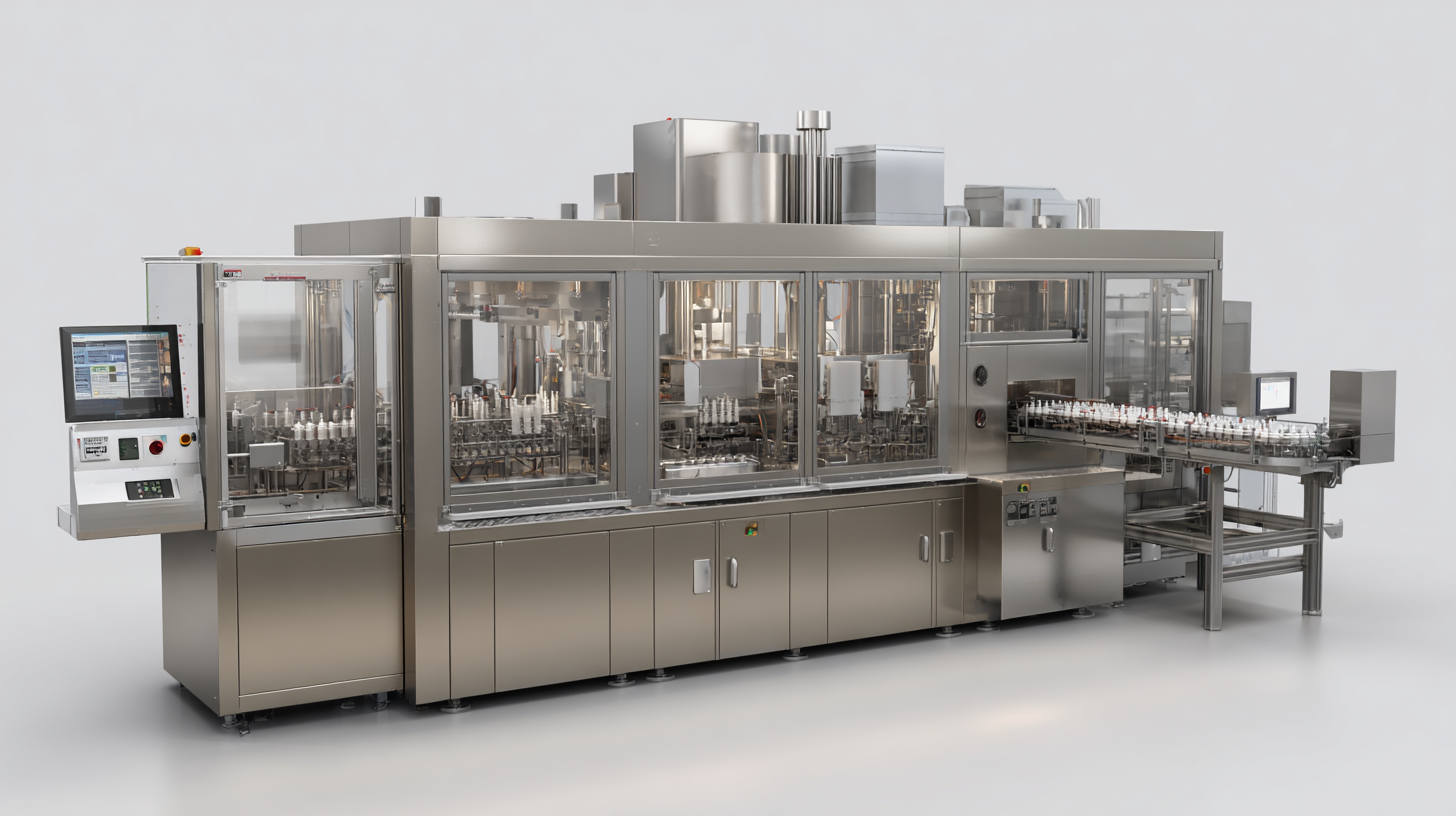

As we approach the year 2025, the landscape of manufacturing continues to evolve, presenting exciting opportunities and challenges in various industries. Among these advancements, filling machines stand out as a critical component driving efficiency and precision in production lines worldwide. With a significant focus on innovation and the integration of cutting-edge technologies, manufacturers are redefining their strategies to enhance productivity and meet the ever-increasing demands of consumers.

This blog will delve into the future of filling machines, examining the latest trends, technological breakthroughs, and implementation strategies that prioritize quality and sustainability. We will explore how global leaders in manufacturing, particularly those from China, are setting the standard for excellence in the filling machinery market, ensuring that their products not only meet but exceed international quality benchmarks.

Join us on this journey to uncover how the filling machines of tomorrow will shape industries and influence production processes in the coming years.

Future Trends in Filling Machine Technology for 2025

As we look ahead to 2025, the landscape of filling machine technology is poised for significant transformations, driven by automation and the integration of smart technology. According to a recent report by Research and Markets, the global filling machine market is expected to grow by over 5.3% annually, reaching a valuation of approximately $6 billion by the end of 2025. This growth will be fueled by the increasing demand for high-speed production capabilities and the need for precision in various industries, including food and beverage, pharmaceuticals, and cosmetics.

One of the most exciting trends is the adoption of Industry 4.0 principles within filling operations, which incorporate IoT (Internet of Things) functionality into traditional machines. This shift allows for real-time data collection and analysis, enabling manufacturers to optimize production processes, reduce downtime, and enhance quality control. Additionally, as sustainability becomes more critical, eco-friendly machine designs that minimize waste and energy consumption are becoming a priority. According to a study by Allied Market Research, the rise in demand for sustainable production practices is leading to an estimated 30% increase in the market for energy-efficient filling machines.

Digital Transformation in Filling Machine Production Standards

The digital transformation of filling machine production standards is poised to revolutionize the industry by 2025. As manufacturers navigate the complexities of Industry 4.0, they are integrating advanced technologies that not only enhance efficiency but also bolster sustainability. Embracing digital processes allows for real-time monitoring and data-driven decision-making, ensuring that filling machines meet stringent production standards and adapt to evolving market demands.

Moreover, the adoption of artificial intelligence and IoT in filling machine operations is streamlining workflows and optimizing outputs. These technologies facilitate predictive maintenance, reducing downtime and enhancing productivity. Companies that harness digital innovation are finding themselves equipped to unlock new levels of efficiency, ultimately leading to improved quality control and reduced operational risks in their manufacturing lines. The focus on connectivity and automation in the production environment marks a significant leap forward, setting the stage for a more resilient and agile manufacturing ecosystem.

Innovative Solutions for Enhanced Efficiency in Filling Processes

In the competitive landscape of 2025, filling machines are set to undergo significant transformations driven by innovative solutions that enhance efficiency. The integration of artificial intelligence in the manufacturing process marks a pivotal shift, optimizing operations from formulation development to quality control. By focusing on real-time data analysis and machine learning algorithms, these advancements ensure that filling processes are not only faster but also more accurate, reducing errors and waste significantly.

Additionally, new technologies such as RFID-enabled systems are emerging, enhancing traceability in the fill and finish stages. This ensures that manufacturers can maintain stringent quality standards while improving product integrity. Sustainable practices are also at the forefront, with advancements in thermal-driven dehumidification systems that contribute to maintaining ideal conditions during filling processes. The future of filling machines is not only about speed but also about creating a more sustainable and efficient operational paradigm, positioning companies for long-term success in an increasingly automated world.

Key Drivers Behind the Evolution of Filling Machine Innovations

The evolution of filling machines is primarily driven by technological advancements, consumer demand for efficiency, and the increasing focus on sustainability.

As industries seek to enhance productivity, automation in filling machines is becoming a crucial component. Innovative technologies such as artificial intelligence and machine learning are being integrated to optimize filling processes, reduce downtime, and improve accuracy. These innovations allow manufacturers to respond swiftly to market changes and customer preferences while maintaining high operational standards.

Additionally, the rising demand for environmentally friendly packaging solutions is reshaping filling machine designs. Manufacturers are exploring materials that are biodegradable and recyclable, which aligns with global sustainability goals. The implementation of smart technologies in filling machines not only promotes waste reduction but also supports traceability in packaging.

As these drivers continue to shape the landscape, the future of filling machines looks promising, harnessing cutting-edge solutions to meet the needs of both producers and consumers alike.

Implementation Strategies for Adopting Advanced Filling Technologies

As the landscape of food and beverage production continues to evolve, adopting advanced filling technologies in 2025 will be pivotal for manufacturers looking to enhance efficiency and meet growing consumer demands. Implementation strategies focused on integrating these innovations will ensure a smooth transition and maximize operational benefits. Key steps for successful adoption include thorough needs assessment, which allows companies to identify gaps in current processes and pinpoint the specific technologies required to bridge those gaps.

Another critical strategy is investing in employee training to foster a culture that embraces change. With the introduction of advanced filling machines, it's essential to equip teams with the knowledge and skills to operate and maintain new equipment effectively. Furthermore, collaborating with technology providers can facilitate tailored solutions that align with specific production requirements, ensuring that the integration process is both efficient and effective. By prioritizing these strategies, manufacturers can not only improve their filling operations but also stay ahead in a rapidly changing industry.