Exploring the Future of Packaging with Best Heat Sealing Machine Innovations by 2025

The packaging industry is poised for significant transformations by 2025, particularly with advancements in heat sealing machine technologies. As reported by MarketsandMarkets, the global packaging machinery market is expected to reach USD 56.6 billion by 2024, growing at a CAGR of 6.6% during 2019-2024. One of the crucial components driving this growth is the heat sealing machine, which ensures the integrity and shelf life of products across various sectors, including food and pharmaceuticals. Meeting stringent standards for quality and sustainability is becoming paramount, thereby highlighting the importance of sourcing from reputable suppliers. As businesses strive to enhance operational efficiency and reduce waste, understanding how to identify and partner with high-quality suppliers of heat sealing machines will be essential for navigating the evolving landscape of packaging innovations.

Emerging Trends in Heat Sealing Technologies for Sustainable Packaging Solutions

As the packaging industry continues to evolve, the focus on sustainable solutions is becoming increasingly prevalent. Emerging trends in heat sealing technologies are paving the way for environmentally friendly packaging options. Innovations such as heat-sealable coatings made from safe, recyclable materials not only enhance product safety but also support the recycling process. Companies are exploring new formulations that minimize environmental impact, demonstrating a commitment to sustainability while maintaining the integrity and performance of their packaging.

Key Innovations in Heat Sealing Machines Enhancing Efficiency and Performance

The packaging industry is undergoing a significant transformation, driven by cutting-edge innovations in heat sealing machines. As we look towards 2025, key advancements are poised to enhance both efficiency and performance in packaging processes. Reports indicate that the heat sealing machine market is expected to grow substantially, with a projected CAGR of 6.2% from 2021 to 2026, driven by the increasing demand for high-quality packaging solutions across various sectors.

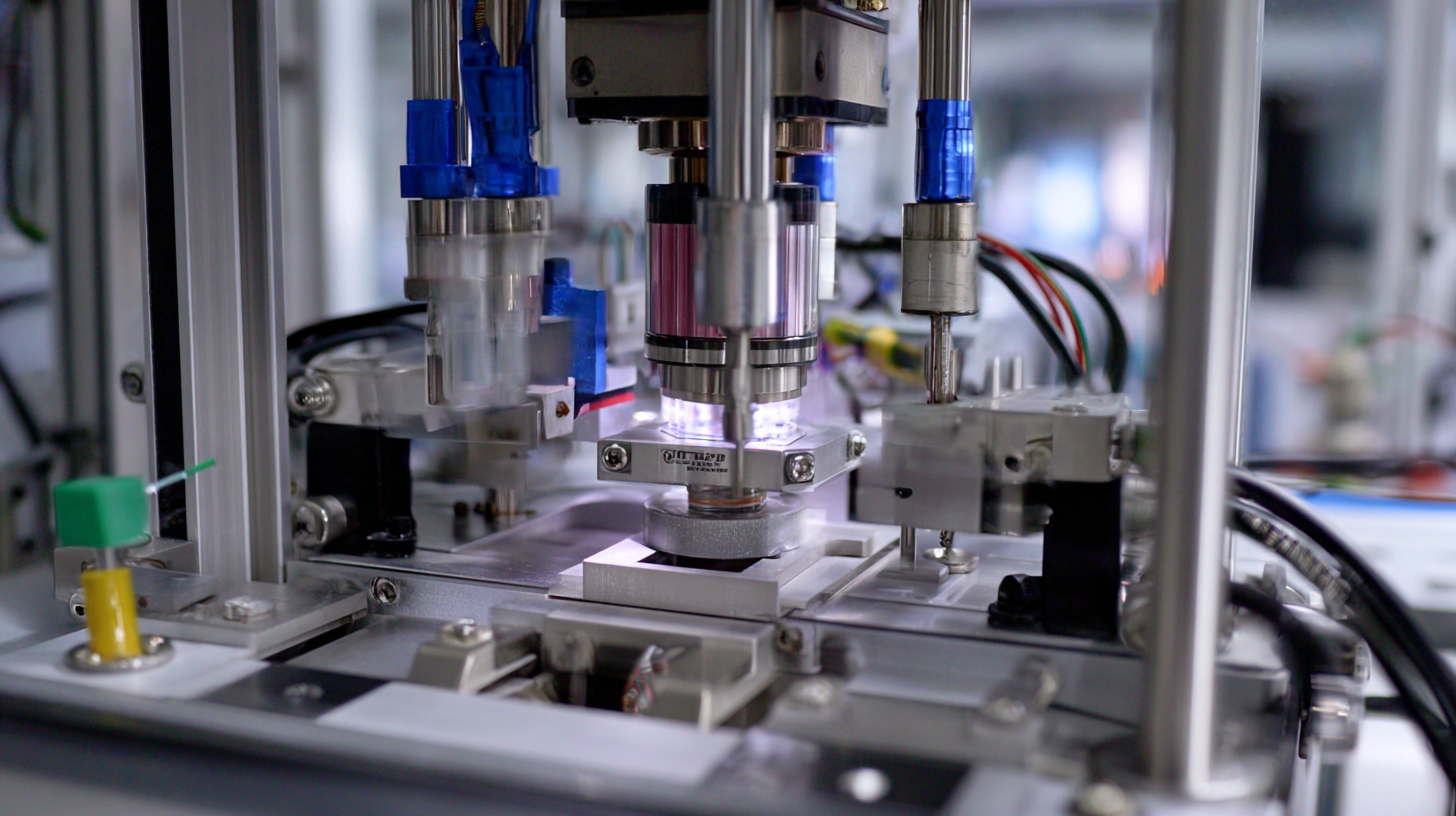

Innovations such as advanced sealing technologies, including ultrasonic and impulse sealing, are enhancing the integrity and durability of seals. These technologies not only improve the efficiency of the sealing process but also reduce energy consumption. Additionally, the integration of smart technology in heat sealing machines enables real-time monitoring and data analytics, allowing manufacturers to optimize their production lines. According to a market analysis from Fortune Business Insights, the global smart packaging market is projected to reach $56.26 billion by 2027, highlighting the growing importance of intelligent solutions in enhancing operational efficiency.

Furthermore, sustainable packaging solutions are on the rise, with many manufacturers adopting heat sealing machines that utilize biodegradable or recyclable materials. Research by Smithers Pira forecasts that environmentally friendly packaging will represent 24% of the global packaging market by 2024, emphasizing the need for innovative sealing methods that align with sustainability goals. As these trends continue to evolve, the future of heat sealing technology holds promising potential for revolutionizing packaging practices and meeting the demands of an increasingly eco-conscious consumer base.

Market Insights: Projected Growth of the Heat Sealing Equipment Sector by 2025

The heat sealing equipment sector is poised for significant growth by 2025, driven by advancements in technology and increasing demand for efficient packaging solutions. As industries pivot towards sustainability, manufacturers are innovating their heat sealing machines to utilize eco-friendly materials and reduce waste. With a projected compound annual growth rate (CAGR) of over 5%, the market is attracting investment and encouraging startups to develop cutting-edge designs that enhance productivity.

One of the defining trends in this sector is the integration of smart technology into heat sealing machines. These innovations allow for precise temperature control and real-time monitoring, minimizing product spoilage and maximizing efficiency. Additionally, the rise of e-commerce has amplified the need for reliable packaging that can withstand logistics challenges, further propelling the demand for advanced heat sealing solutions. As we edge closer to 2025, we can expect these advancements not only to transform the packaging industry but also to foster a more sustainable future.

Exploring the Future of Packaging with Best Heat Sealing Machine Innovations by 2025

| Year | Market Size (in Billion USD) | Projected Growth Rate (%) | Key Innovations | Applications |

|---|---|---|---|---|

| 2023 | 3.5 | 5.2 | Automated sealing technology, Eco-friendly materials | Food & Beverages, Electronics |

| 2024 | 3.75 | 6.3 | Smart sealing machines, Improved energy efficiency | Pharmaceuticals, Cosmetics |

| 2025 | 4.1 | 7.5 | AI integration, Predictive maintenance | Agriculture, Retail |

Critical Features to Consider When Selecting a Heat Sealing Machine

When selecting a heat sealing machine, several critical features must be prioritized to ensure optimal performance and efficiency. One of the most important factors is the type of seal required, which can vary depending on the materials being used and the intended application. A machine that offers versatility, allowing for different sealing methods (such as impulse sealing or continuous sealing), is essential for businesses that deal with various packaging requirements.

Another vital consideration is the machine’s temperature control capabilities. Precise temperature settings can significantly impact the quality of the seal and the integrity of the packaged product. Machines equipped with advanced temperature controllers can adapt to fluctuations in material composition and thickness, ensuring a consistent and secure seal every time. Additionally, ease of use and maintenance should not be overlooked; a user-friendly interface and accessible components can enhance productivity and reduce downtime, making operations smoother and more efficient.

Comparative Analysis of Traditional vs. Smart Heat Sealing Machines in Packaging

In the ever-evolving world of packaging, the choice between traditional and smart heat sealing machines has become increasingly significant. Traditional machines have long been the backbone of packaging, offering reliability and simplicity. They operate at consistent speeds and temperatures, making them suitable for a wide range of products. However, as market demands intensify, these machines struggle to keep up with the need for efficiency and versatility. Companies relying solely on traditional methods may find themselves at a disadvantage, especially when it comes to scaling operations and adapting to new packaging materials.

In the ever-evolving world of packaging, the choice between traditional and smart heat sealing machines has become increasingly significant. Traditional machines have long been the backbone of packaging, offering reliability and simplicity. They operate at consistent speeds and temperatures, making them suitable for a wide range of products. However, as market demands intensify, these machines struggle to keep up with the need for efficiency and versatility. Companies relying solely on traditional methods may find themselves at a disadvantage, especially when it comes to scaling operations and adapting to new packaging materials.

On the other hand, smart heat sealing machines are revolutionizing the packaging landscape. Equipped with advanced technologies such as IoT connectivity and real-time monitoring, these machines not only enhance precision in the sealing process but also improve energy efficiency. They allow operators to track performance metrics and make real-time adjustments, leading to reduced downtime and waste. As businesses shift towards more sustainable practices, the ability to integrate smart technology into packaging systems will prove invaluable. By 2025, those who invest in these innovations are likely to set themselves apart in a competitive marketplace, aligning operational efficiency with modern consumer expectations.