Mastering the Art of Filling Machines A Comprehensive Guide for Beginners

In today's fast-paced manufacturing environment, mastering the art of filling machines is essential for businesses looking to enhance their operational efficiency and meet growing market demands. According to a recent report by Research and Markets, the global filling machine market is expected to reach $5.5 billion by 2027, with a CAGR of 4.8% from 2020 to 2027. As industries continue to evolve, the need for reliable and precise filling solutions has never been greater, making it imperative for beginners to understand the intricacies of selecting and operating filling machines. This comprehensive guide will provide essential tips and insights, empowering newcomers to navigate the complexities of this vital equipment and optimize their production processes effectively. By delving into the best practices and innovations in filling technology, you can position your business for success in a competitive landscape.

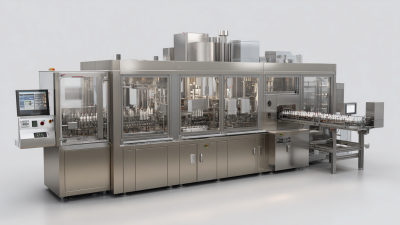

Understanding Different Types of Filling Machines and Their Applications

Filling machines are essential equipment in various industries, from food and beverage to pharmaceuticals, ensuring that products are packaged efficiently and accurately. Understanding the different types of filling machines is crucial for anyone looking to enter this field. Generally, filling machines can be categorized into volumetric, gravimetric, and time-based systems. Volumetric fillers measure a specific quantity of product, making them ideal for liquids, powders, and granules. Gravimetric fillers, on the other hand, utilize weight to determine the appropriate amount, providing precision that is critical in industries where every gram counts.

Moreover, the application of these machines varies widely depending on the product being filled. For instance, liquid filling machines are widely used for beverages and detergents, where a quick fill rate and cleanliness are of utmost importance. In contrast, semi-automatic and automatic powder fillers are designed for products like spices and pharmaceuticals, where dosing accuracy is paramount. By understanding the applications and functionalities of each type, beginners can make informed choices that optimize production efficiency, reduce waste, and enhance product quality.

Mastering the Art of Filling Machines A Comprehensive Guide for Beginners

| Type of Filling Machine | Description | Applications | Advantages |

|---|---|---|---|

| Gravity Filler | Uses gravitational force to fill containers. | Liquid products like water, juice, and oil. | Simple design, low cost, and easy to operate. |

| Piston Filler | Uses a piston to draw and dispense product. | Thicker liquids and semi-liquids like sauces and creams. | High accuracy and can handle various viscosities. |

| Pressure Filler | Fills products under pressure to avoid foaming. | Carbonated beverages and other foamy liquids. | Minimizes product aeration and maximizes filling speed. |

| Volumetric Filler | Measures a specific volume of product for filling. | Various liquids including chemicals and detergents. | Provides consistent fill levels and speed. |

| Auger Filler | Uses a screw mechanism to dispense powdered products. | Powders, grains, and granulated products. | Highly accurate for dry products and adjustable fill weights. |

Key Components of Filling Machines: What Every Beginner Should Know

Filling machines are essential tools in various industries, including food, pharmaceuticals, and cosmetics, where precision and efficiency are paramount. For beginners entering this field, understanding the key components of filling machines is crucial. One of the primary components is the filling head, which determines the speed and accuracy of the filling process. According to a report by MarketsandMarkets, the global filling machines market is projected to reach $7.46 billion by 2025, highlighting the demand for efficient filling solutions that rely heavily on the correct setup and functioning of the filling head.

Another vital component to consider is the conveyor system, which facilitates the smooth movement of products to and from the filling stations. A well-designed conveyor can significantly reduce operational downtime and enhance productivity. For instance, research by Research and Markets states that incorporating automated conveyor systems can boost production efficiency by up to 30%. Additionally, understanding the importance of the control system that monitors filling rates and ensures quality control is critical in maintaining product consistency and minimizing waste. As beginners navigate the complexities of filling machines, focusing on these key components will lay a solid foundation for mastering the technology.

Step-by-Step Guide to Operating a Filling Machine Safely

Operating a filling machine safely is crucial for ensuring both product quality and worker safety. According to a report by the International Society for Automation, nearly 30% of workplace accidents in manufacturing involve machinery, highlighting the importance of proper training and adherence to safety protocols. Beginners should familiarize themselves with the machine’s user manual and safety features, such as emergency stop buttons and safety guards, before attempting to operate the equipment.

The Occupational Safety and Health Administration (OSHA) emphasizes the significance of proper training programs, which can reduce accidents by up to 50%. New operators should engage in hands-on training sessions under the supervision of experienced personnel. Understanding the machine's operational limits, including maximum fill speeds and capacities, is essential to prevent malfunctions and ensure consistent filling accuracy.

Regular maintenance and safety checks, coupled with a clear understanding of operating procedures, will enhance not only the efficiency of the filling process but also the well-being of all personnel involved.

Common Challenges in Filling Machine Operations and How to Overcome Them

Filling machines are critical in various industries, from food and beverage to pharmaceuticals. However, beginners often face challenges that can hinder their operations. One common issue is inaccurate filling, which can result in product waste or customer complaints. To combat this, it’s essential to calibrate the machine regularly and conduct thorough testing of the filling parameters. By maintaining consistent measurements and adjusting the filling volume, operators can ensure precision and minimize discrepancies.

Another challenge is dealing with different container types and sizes, which can complicate the filling process. Many machines may struggle with inconsistent flow rates when handling varying viscosities, leading to inefficiencies. To overcome this challenge, operators should invest in adjustable filling heads and nozzles that cater to a diverse range of products. Additionally, training on quick adjustments to the machinery can empower operators to switch between products seamlessly, optimizing production efficiency and reducing downtime. By addressing these common hurdles, beginners can enhance their filling machine operations and ensure smoother workflows.

Maintenance Tips for Ensuring Longevity and Efficiency of Filling Machines

Maintaining filling machines is crucial for ensuring their longevity and optimal efficiency. Regular maintenance not only extends the life of the equipment but also minimizes downtime and enhances production quality. Begin by establishing a routine maintenance schedule that includes routine inspections of all mechanical components, such as pumps and nozzles. Keeping these parts clean and lubricated can prevent costly breakdowns and ensure smooth operation.

In addition to mechanical checks, it's essential to monitor the calibration of the filling machines. Inaccurate filling can lead to wasted materials and dissatisfied customers. Periodic recalibration ensures that your machines dispense precise volumes consistently. Additionally, train your staff to recognize early signs of wear and tear, as their experience on the floor can provide valuable insights. Implementing these maintenance tips will not only boost the efficiency of your filling machines but also create a safer and more productive working environment.

Mastering Filling Machines: Efficiency and Maintenance Insights

This chart illustrates the average maintenance frequency and efficiency ratings of various filling machine types based on recent industry data. Understanding these metrics can help in choosing the right machine for specific needs.

Related Posts

-

Understanding the Challenges of Filling Machines in Global Supply Chains

-

Analyzing the Market Potential for Best Filling Machines in 2025 and Beyond

-

Exploring the Future of Filling Machines in 2025 Innovations and Implementation Strategies

-

How to Select the Best Packaging Equipment for Your Global Supply Chain: A Comprehensive Tutorial

-

How to Select Reliable Manufacturers for Food Tray Sealing Machines 7 Expert Tips

-

Essential Export Certifications for Sourcing Packaging Equipment Globally