Maximizing Efficiency: The Advantages of the Best Tray Sealing Machine in Food Packaging

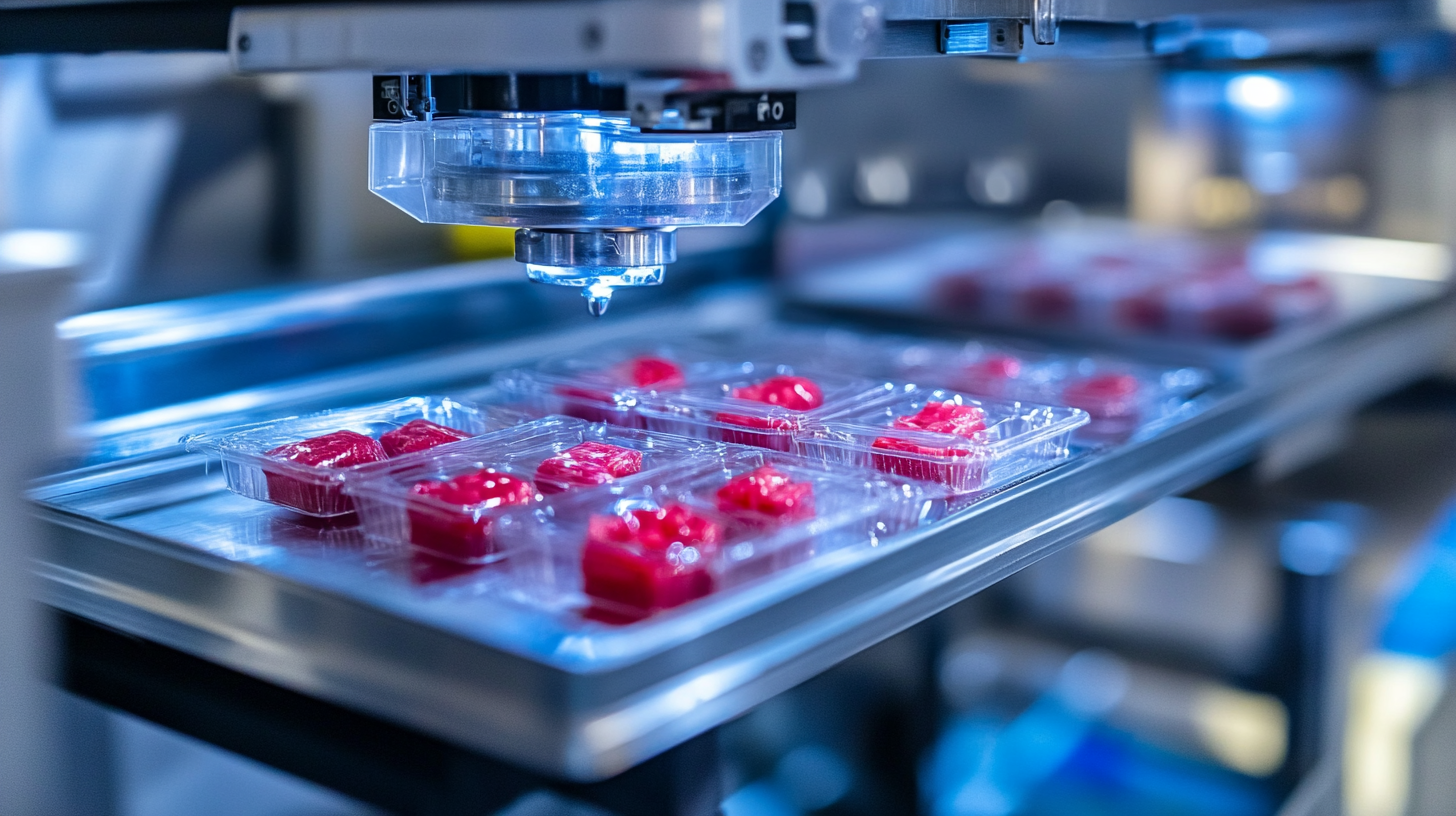

In the ever-evolving world of food packaging, optimizing efficiency is crucial for manufacturers aiming to enhance productivity while ensuring product integrity. One of the most effective solutions available on the market today is the tray sealing machine, which combines precision, speed, and versatility to meet the diverse needs of food producers. This advanced technology streamlines the packaging process by securely sealing a variety of food items in trays, prolonging shelf life and reducing waste. With detailed technical parameters that highlight their capabilities, such as sealing speed, energy consumption, and adaptability to different tray types, the best tray sealing machines stand out in the industry. Investing in these machines not only boosts operational efficiency but also enhances the overall packaging quality, making it essential for any food packaging business looking to remain competitive in a rapidly changing market.

Understanding Tray Sealing Technology: What Makes the Best Machines Stand Out

Tray sealing technology is revolutionizing the food packaging industry, offering advantages that are hard to overlook. The best tray sealing machines stand out due to their innovative designs and advanced features that streamline the packaging process. These machines utilize temperature and pressure controls that ensure airtight seals, which preserve the freshness and extend the shelf life of various food products. Additionally, they are equipped with user-friendly interfaces that allow operators to easily adjust settings according to different packaging requirements, enhancing overall efficiency.

Moreover, the versatility of high-quality tray sealing machines is another distinguishing factor. They can accommodate a wide range of materials, including plastics, foils, and biodegradable options, catering to the growing demand for sustainable packaging solutions. The ability to work with different tray sizes and shapes also allows manufacturers to customize their packaging strategies, improving brand presentation while reducing waste. This adaptability not only meets consumer needs but also helps companies stay competitive in a rapidly evolving market.

Maximizing Efficiency: The Advantages of the Best Tray Sealing Machine in Food Packaging

| Feature | Description | Benefits |

|---|---|---|

| Sealing Speed | Up to 20 trays per minute | Increased production rate and reduced packaging time |

| Energy Efficiency | Low energy consumption | Cost savings and reduced carbon footprint |

| Versatility | Compatible with a variety of tray materials and sizes | Flexibility in packaging different products |

| Automatic Operation | Fully automated sealing process | Reduced labor costs and minimized human error |

| Quality Control | Integrated quality monitoring systems | Assured high quality and consistency of sealed trays |

Key Features of Top Tray Sealing Machines: Efficiency and Performance Metrics

In the food packaging industry, selecting the right equipment can greatly impact efficiency and product integrity. Top tray sealing machines come equipped with features that enhance their performance, ensuring that food is packed securely while maintaining freshness. Key metrics to consider include sealing speed, temperature control, and the ability to handle various tray sizes. Machines with adjustable settings allow operators to customize the sealing process, minimizing waste and maximizing throughput.

In the food packaging industry, selecting the right equipment can greatly impact efficiency and product integrity. Top tray sealing machines come equipped with features that enhance their performance, ensuring that food is packed securely while maintaining freshness. Key metrics to consider include sealing speed, temperature control, and the ability to handle various tray sizes. Machines with adjustable settings allow operators to customize the sealing process, minimizing waste and maximizing throughput.

Tip: When choosing a tray sealing machine, look for models with automatic control systems that monitor sealing cycles. These systems reduce human error and maintain consistent quality across packed products.

Another important feature is the machine's ease of use and maintenance. A user-friendly interface can significantly reduce training time for staff, while machines designed for quick maintenance can improve uptime. Additionally, advanced machines might offer features like vacuum sealing and modified atmosphere packaging, which can further enhance the longevity of food products.

Tip: Consider investing in a tray sealing machine with integrated cleaning functions, which can streamline maintenance and ensure hygienic operations in a fast-paced environment.

How the Right Tray Sealing Machine Enhances Food Safety and Freshness

In the ever-evolving food packaging industry, the right tray sealing machine plays a pivotal role in enhancing food safety and freshness. By creating an airtight seal, these machines effectively minimize the risk of contamination, thereby preserving the product's quality over time. The technology behind tray sealing has advanced significantly, allowing for precise temperature and pressure control. This ensures that food products not only stay fresh longer but also retain their flavors and nutritional value, offering consumers a superior eating experience.

Moreover, the use of high-quality materials in modern tray sealers contributes to increased shelf life. Many machines now utilize recyclable and sustainable materials, addressing environmental concerns while ensuring that safety standards are met. The ability to securely package foods in a way that is tamper-resistant not only strengthens consumer trust but also reduces waste. As a result, the right tray sealing machine not only boosts operational efficiency but also plays a vital role in ensuring that food reaches consumers in the safest and freshest state possible.

Cost-Effectiveness: Long-Term Savings with the Best Tray Sealing Solutions

In today's competitive food packaging industry, cost-effectiveness is a primary concern for businesses striving to maximize their profit margins. Investing in high-quality tray sealing machines can significantly impact long-term savings. According to a report by MarketsandMarkets, the global tray sealing market is projected to reach USD 2.5 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is driven by the rising demand for ready-to-eat meals and increased shelf life of packaged foods, which directly relates to the efficiency of the sealing process.

A top-tier tray sealing machine not only enhances packaging quality but also reduces material waste. For instance, advanced machines utilize precise temperature control and seal time adjustments to minimize excess packaging material usage. The 2022 Packaging Industry Report highlighted that businesses using automated tray sealing solutions reduced their packaging costs by up to 30%, as they effectively optimized the entire sealing process, providing consistent seals and reduced spoilage rates. By integrating these machines, companies can significantly lower operational costs while ensuring that products remain fresh and appealing to consumers.

Innovations in Tray Sealing: The Future of Food Packaging Efficiency

In recent years, innovations in tray sealing technology have ushered in a new era of efficiency in food packaging. By utilizing advanced materials and automated processes, the best tray sealing machines are designed to optimize productivity while ensuring optimal sealing performance. These machines not only reduce food spoilage but also enhance shelf life, making them an indispensable asset for food manufacturers aiming to maintain high-quality standards.

Moreover, the future of food packaging lies in the integration of smart technology within tray sealing systems. With the advent of IoT-enabled devices, manufacturers can now monitor and manage their packaging lines in real-time, allowing for quicker adjustments and minimizing downtime. This level of innovation promises to not only streamline operations but also improve sustainability by reducing waste and energy consumption—critical factors in today’s environmentally conscious market. As these technologies continue to evolve, the industry will see a shift towards more efficient, reliable, and sustainable food packaging solutions.

Maximizing Efficiency in Food Packaging: Tray Sealing Machine Performance

This chart displays the efficiency percentages of several leading tray sealing machines. As seen, Machine D demonstrates the highest efficiency at 95%, showcasing the advancements in technology and design that enhance food packaging processes.