Revolutionizing Efficiency: The Future of Packaging Machinery in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, packaging machinery is poised to play a pivotal role in enhancing operational efficiency and sustainability. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $60 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.4%. This surge is driven by increasing consumer demand for faster production, improved automation, and innovative packaging solutions that not only safeguard products but also reduce environmental impact. As manufacturers turn to advanced technologies such as robotics, IoT, and machine learning, the future of packaging machinery promises to optimize processes and drive significant cost savings. By embracing these innovations, companies can not only meet regulatory standards but also elevate their competitive edge in a dynamic marketplace.

The Impact of Automation on Packaging Efficiency and Cost Reduction

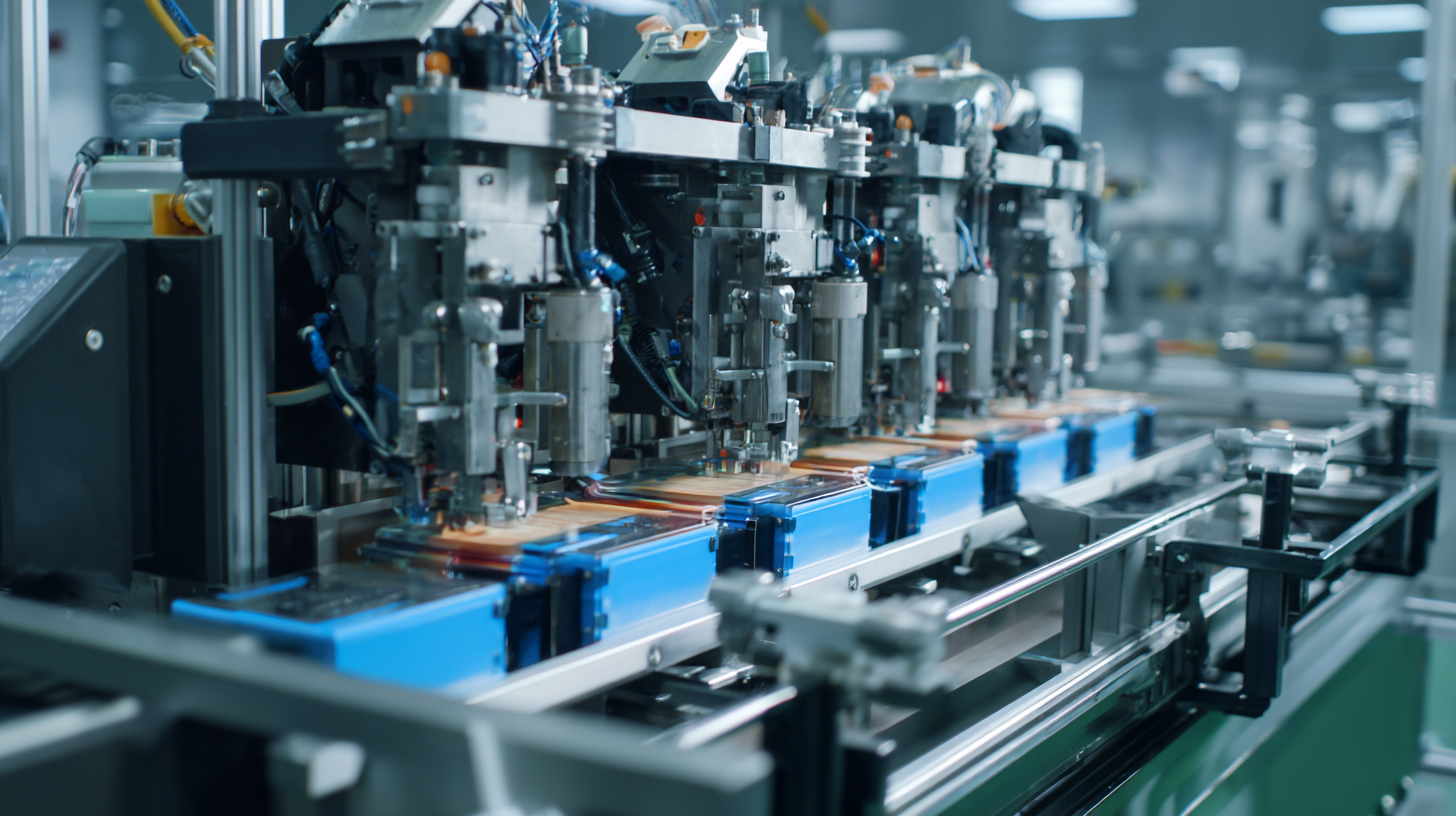

The integration of automation in packaging machinery is transforming manufacturing processes, leading to significant improvements in efficiency and cost management. Automated systems streamline packaging tasks, eliminating time-consuming manual operations and reducing the likelihood of human error. As a result, manufacturers can achieve higher output rates and improved consistency in product presentation, essential in competitive markets where speed and quality are paramount.

Moreover, the financial implications of automation are profound. By investing in advanced packaging technology, companies can minimize labor costs and reduce material wastage. Automation systems can be programmed for optimized resource usage, adjusting processes in real-time to enhance productivity. This adaptability not only lowers operational costs but also empowers manufacturers to respond swiftly to market demands, enhancing their overall competitiveness and ensuring long-term sustainability in manufacturing practices.

Integrating Smart Technology in Packaging Machinery: A Step-by-Step Guide

The integration of smart technology into packaging machinery is set to transform the landscape of modern manufacturing. As manufacturers strive for greater efficiency and productivity, adopting advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning becomes essential. These innovations enable packaging machines to communicate seamlessly with each other, monitor performance in real-time, and predict maintenance needs, thus significantly reducing downtime and operational costs.

Implementing smart technology in packaging machinery involves a step-by-step approach. First, manufacturers must assess their current systems and identify areas where automation can enhance efficiency. Next, investing in connected devices and software solutions that offer data analytics capabilities is crucial for monitoring operations. Training personnel to utilize these technologies effectively ensures that human resources are aligned with the machinery’s advanced functionalities. Lastly, continuous evaluation and updates to the smart systems will help maintain their effectiveness, ensuring the manufacturing process remains agile and responsive to market demands. This progressive integration promises not only to streamline packaging processes but also to elevate overall production quality.

How Big Data Analytics Can Transform Packaging Processes in Manufacturing

In modern manufacturing, the integration of big data analytics into packaging processes is catalyzing a significant transformation in efficiency and productivity. By harnessing vast amounts of data generated throughout production, manufacturers can gain insights that were previously overlooked. For instance, analyzing data from packaging lines allows for real-time monitoring of machinery performance and product quality, enabling instant adjustments that minimize waste and reduce downtime. Predictive analytics can forecast potential bottlenecks, making it possible to streamline operations and ensure that packaging processes remain agile.

Moreover, big data analytics can enhance supply chain management in packaging. By analyzing consumer behavior and market trends, manufacturers can optimize their packaging designs and materials to meet the demands of the market efficiently. This responsiveness not only leads to cost savings but also improves customer satisfaction by ensuring that products are delivered in a timely and well-packaged manner. As manufacturers continue to embrace these advanced analytical techniques, the future of packaging machinery looks poised for a revolution that prioritizes sustainability, efficiency, and adaptability in an ever-evolving market landscape.

Sustainability Trends in Packaging Machinery: Innovations for a Greener Future

Sustainability has become a pivotal focus within the packaging machinery industry, driven by both consumer demand and regulatory pressures. The shift towards greener practices has led manufacturers to innovate solutions that minimize environmental impact. For instance, advancements in biodegradable materials and energy-efficient machinery are transforming traditional packaging processes. Companies are increasingly adopting technologies that reduce waste and energy consumption, such as automation and intelligent systems that optimize resource usage.

Moreover, the integration of recyclable materials into packaging solutions is gaining traction. Manufacturers are now exploring ways to create packaging that not only protects products but also contributes positively to the environment post-use. Innovations like reusable packaging systems and compostable materials are examples of how the industry is evolving. The development of these sustainable packaging machinery solutions is not just an ethical necessity but also a response to market demands for environmentally friendly products, demonstrating a clear pathway toward a more sustainable future in manufacturing.

Revolutionizing Efficiency: The Future of Packaging Machinery in Modern Manufacturing

This chart represents the percentage of manufacturing companies adopting sustainable packaging machinery innovations over the past five years. The data reflects trends in efficiency and sustainability, showcasing the growing importance of eco-friendly practices in the industry.

The Role of Robotics in Enhancing Speed and Precision in Packaging Operations

The integration of robotics into packaging operations is profoundly transforming the manufacturing landscape. Robotics enhance speed and precision, reducing human error and allowing for faster production lines. Automated packaging systems are designed to handle a variety of products efficiently, optimizing packing processes from start to finish. The result is not only a boost in productivity but also significant cost savings over time.

The integration of robotics into packaging operations is profoundly transforming the manufacturing landscape. Robotics enhance speed and precision, reducing human error and allowing for faster production lines. Automated packaging systems are designed to handle a variety of products efficiently, optimizing packing processes from start to finish. The result is not only a boost in productivity but also significant cost savings over time.

Tips for Implementing Robotics in Packaging:

1. Start small by automating one segment of your packaging line to evaluate the impact on efficiency and effectiveness.

2. Invest in training for your workforce to ensure they are equipped to work alongside robots, making the transition smoother and more productive.

3. Regularly assess your robotic systems for performance and identify any areas for improvement to maintain a competitive edge.

As manufacturers look toward the future, embracing robotics in packaging is a strategic move that promises enhanced operational capabilities. By harnessing these advanced technologies, companies can stay ahead of market demands while delivering quality products with remarkable efficiency.

Related Posts

-

7 Compelling Benefits of Investing in Packaging Machinery for Your Business

-

Understanding Global Standards for Importing Packaging Machinery Step by Step Guide

-

Evaluating Different Types of Packaging Machinery for Your Business Needs

-

Essential Guide to Choosing the Right Packaging Machines for Your Business Needs

-

Understanding Challenges in Sourcing Packaging Machines for Global Supply Chains

-

Top 10 Packaging Machine Manufacturers from China at the 137th Canton Fair