What is Stainless Steel Wire Mesh and Its Uses?

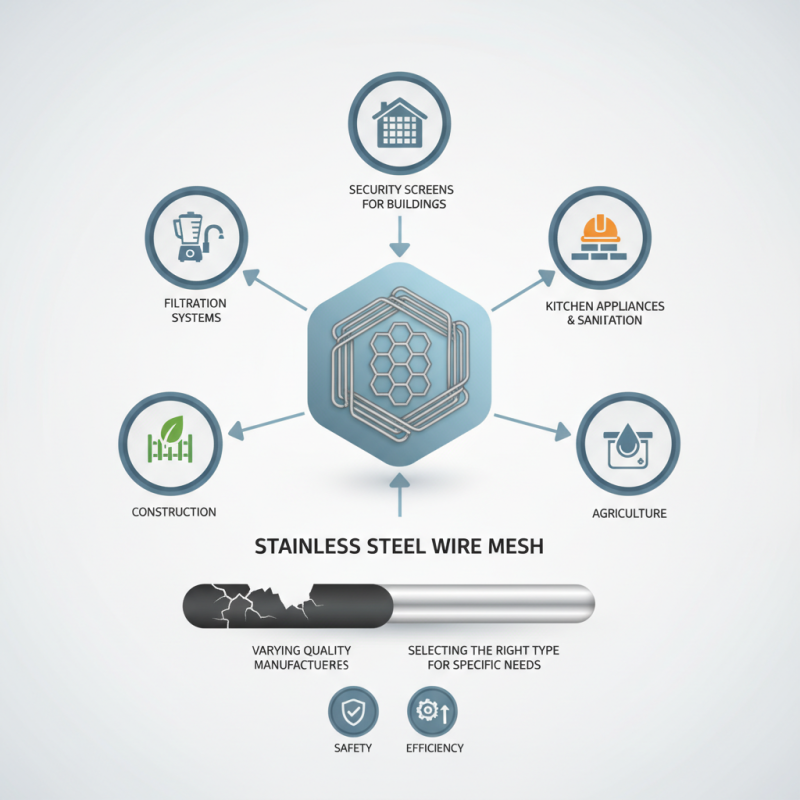

stainless steel wire mesh is a versatile material with a range of applications. It is made from durable stainless steel, offering strength and resistance to corrosion. This makes it ideal for various industries, including construction, agriculture, and filtration systems.

Many people might not realize how prevalent stainless steel wire mesh is in everyday life. For instance, it is often used in security screens for buildings. Additionally, it plays a vital role in kitchen appliances and equipment that require sanitation. Understanding its uses can spark ideas for different applications.

Yet, not all stainless steel wire mesh is created equal. Quality can vary greatly among manufacturers. It is essential to select the right type for specific needs. Reflection on this choice can lead to better outcomes in both safety and efficiency.

What is Stainless Steel Wire Mesh?

Stainless steel wire mesh is a versatile material made from stainless steel wires woven together. This mesh displays remarkable durability and resistance to rust and corrosion. It comes in various sizes and styles, making it suitable for different applications. From industrial to decorative uses, its adaptability is impressive.

In construction, stainless steel wire mesh strengthens concrete structures. It enhances safety in buildings, ensuring stability. For filtration, this mesh allows for precise separation of materials. It is used in food processing, water treatment, and chemical industries. Every application highlights its unique properties and benefits.

However, the production process can sometimes lead to inconsistencies. Slight variations in wire thickness or weave may occur. These imperfections can affect performance in specific uses. It is vital to choose the right mesh for the intended purpose. Careful consideration can lead to better results and reduce potential issues. Being aware of these factors is crucial in selecting the appropriate stainless steel wire mesh for your needs.

Composition and Manufacturing Process of Stainless Steel Wire Mesh

Stainless steel wire mesh is made from several components. The primary one is stainless steel, an alloy of iron, chromium, and nickel. This combination provides rust resistance and high strength. Other elements can be added to enhance specific properties. For example, molybdenum improves corrosion resistance, while carbon increases strength. Each type of stainless steel brings unique characteristics to the wire mesh.

The manufacturing process involves several stages. Initially, raw materials are melted together in a furnace. Once the alloy is ready, it is cast into shapes. After that, the steel is drawn into wire using a series of progressive dies. This process often requires multiple passes. Each pass reduces the diameter of the wire. It is critical to maintain quality throughout. Any flaws can affect the final product's performance. Afterward, the wire is woven into mesh using various techniques. Each weaving method creates different patterns and strengths. Factors like wire diameter and mesh opening size also come into play. These details cater to diverse applications in construction, agriculture, and filtration.

Stainless Steel Wire Mesh Uses Overview

Common Types of Stainless Steel Wire Mesh and Their Features

Stainless steel wire mesh comes in various types, each serving unique purposes. One common type is welded wire mesh. It consists of perpendicular wires that are welded together at the intersections. This type offers strong structural integrity, making it suitable for construction projects. Another prevalent type is woven wire mesh. The interlaced wires create a flexible design, often used in filtration applications.

The features of stainless steel wire mesh depend on the grade of stainless steel used. For example, 304 stainless steel is widely used for general purposes due to its excellent corrosion resistance. On the other hand, 316 stainless steel has added molybdenum, enhancing its performance in harsher environments. Users should consider their specific needs when choosing a type.

When selecting wire mesh, think about the project's requirements. A finer mesh may filter out smaller particles but could be more prone to clogging. Additionally, if durability is key, opt for welded mesh. It might cost more but offers superior strength. Explore various types and see which fits your situation best. Each variety has strong points but also weaknesses. Reflect on these aspects carefully.

Applications of Stainless Steel Wire Mesh Across Various Industries

Stainless steel wire mesh plays a vital role in many industries. Its durable construction withstands harsh conditions while maintaining structural integrity. This makes it ideal for construction, mining, and food processing.

In construction, stainless steel wire mesh provides reinforcement. It enhances concrete's strength while reducing the weight. In the mining sector, it is used for filtration and separation processes. The mesh captures waste and ensures efficient mineral recovery.

In the food industry, this material prevents contamination. It is used in sieves and conveyors. However, mesh can be hard to clean. Proper maintenance is crucial, demanding reflection on cleaning techniques. While its applications are extensive, oversights in upkeep can lead to inefficiencies.

Benefits of Using Stainless Steel Wire Mesh in Construction and Design

Stainless steel wire mesh is a versatile material used in construction and design. Its benefits are extensive. One major advantage is its durability. Unlike other materials, stainless steel withstands harsh weather. It resists rust and corrosion, making it ideal for outdoor use. This durability increases the longevity of various projects.

When considering stainless steel wire mesh, think about the design aspect too. It provides a modern, sleek aesthetic. Many architects incorporate it into their projects, creating stylish barriers or partitions. The fine mesh lets light filter through while offering privacy. This balance can be difficult to achieve with other materials.

Tips for using stainless steel wire mesh include considering the size and gauge needed for your project. A finer mesh may be better for smaller spaces. However, it can be more expensive. Also, ensure the installation is done correctly. Poor installation can lead to weaknesses. Regularly inspect the mesh for wear to maintain its integrity.

| Dimension | Gauge | Wire Diameter (inches) | Applications |

|---|---|---|---|

| 1/4" | 19 | 0.025 | Construction Safety Fencing |

| 1/2" | 16 | 0.062 | Architectural Applications |

| 3/4" | 14 | 0.080 | Security Screens |

| 1" | 12 | 0.104 | Industrial Flooring |

| 1.5" | 10 | 0.128 | Animal Fencing |

| 2" | 8 | 0.162 | Reinforcement in Concrete |