What is a Steering Cylinder and How Does It Work?

A Steering Cylinder is a critical component in hydraulic steering systems. It helps convert the rotational motion of the steering wheel into linear motion, allowing for smooth and precise vehicle control. Understanding how it functions is essential for anyone dealing with automotive technology.

The Steering Cylinder operates through hydraulic pressure. Fluid is directed into the cylinder, causing a piston to move. This movement assists in steering the wheels. The design of the Steering Cylinder plays a significant role in the overall handling of the vehicle. However, without proper maintenance, it can fail, leading to steering issues.

Many vehicle owners overlook the importance of the Steering Cylinder. This can lead to unexpected problems and costly repairs. Regular checks and fluid changes can enhance its longevity. Not everyone realizes how vital this component is. Taking time to learn about the Steering Cylinder can help ensure a safer driving experience.

What is a Steering Cylinder?

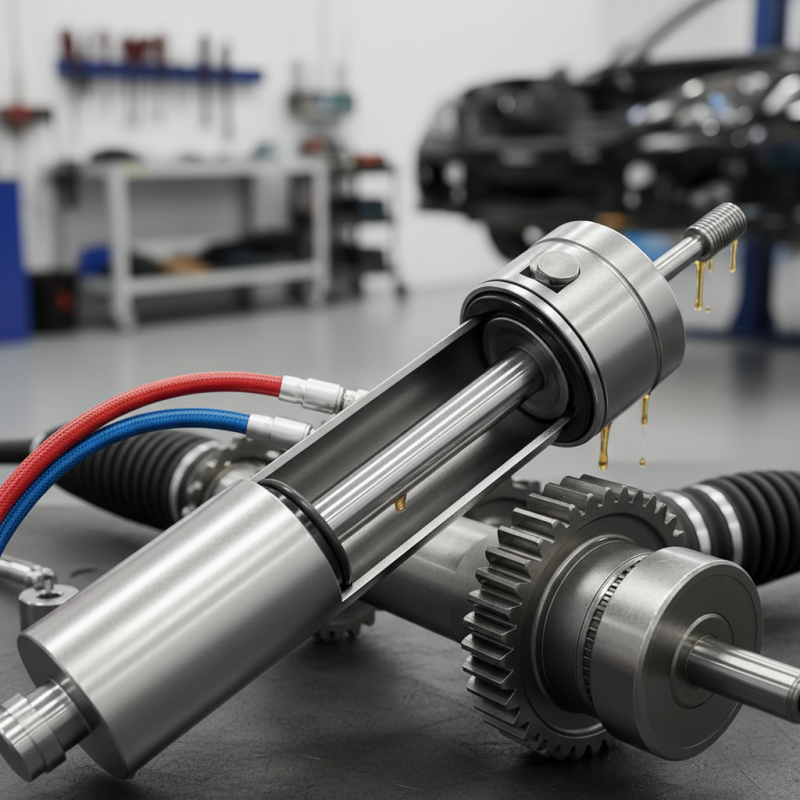

A steering cylinder is a vital component in hydraulic steering systems. It uses hydraulic fluid to create movement, allowing drivers to steer their vehicles effectively. This cylinder consists of a barrel, a piston, and ports for fluid flow. When hydraulic fluid enters the cylinder, it pushes the piston, which turns the vehicle's wheels.

Steering cylinders play a crucial role in heavy machinery and vehicles. They enable precise control, making it easier to navigate tight spaces. However, maintaining them can be tricky. Leaks or air in the system might affect performance. Regular checks and proper maintenance are essential to keep everything running smoothly.

Understanding how a steering cylinder works can improve your driving experience. The feeling of having direct control is satisfying. Yet, not paying attention to these details can lead to significant challenges. Focusing on the little things can prevent bigger problems down the road.

Key Components of a Steering Cylinder

A steering cylinder is a vital component in hydraulic steering systems. It plays a crucial role in vehicle maneuverability. Understanding its key components helps in appreciating how steering operates.

The steering cylinder consists of a few essential parts. The cylinder housing, where the fluid resides, ensures proper sealing. The piston moves within this housing, applying pressure. The end seals maintain hydraulic pressure and prevent leaks. These seals often wear out and can cause issues. The rod transfers the force from the piston to the steering linkage. Each component's effectiveness can vary, affecting performance.

Hydraulic fluid flows through the cylinder, facilitating smooth movements. However, contamination can lead to problems. Regular maintenance is necessary to keep performance optimal. Drivers often overlook these details. The steering cylinder's failure can compromise safety. By understanding its parts better, vehicle owners can take proactive measures.

How Steering Cylinders Operate Mechanically

Steering cylinders are pivotal in the mechanics of vehicle steering systems. They convert hydraulic pressure into linear motion, allowing for precise control of the steering angle. This mechanism operates using a piston within a sealed cylinder. When hydraulic fluid is pumped into the cylinder, it pushes the piston, which then turns the steering mechanism. According to industry reports, about 85% of modern vehicles utilize hydraulic or electro-hydraulic steering systems, enhancing their maneuverability and responsiveness.

The mechanical operation of steering cylinders involves several critical components. A crucial element is the fluid reservoir, which stores hydraulic fluid. The pressure generated by the pump forces this fluid into the cylinder. This process creates the necessary torque to turn the vehicle. However, wear and tear on seals and components can lead to leaks, causing performance issues. Nearly 20% of steering system failures are attributed to hydraulic leaks, highlighting the need for regular maintenance.

In addition, the efficiency of steering cylinders can be influenced by various factors. The quality of hydraulic fluid and the design of the cylinder play significant roles. Research indicates that using high-quality fluid can improve responsiveness by up to 30%. However, not all vehicles are equipped to utilize the best materials, leading to inconsistencies. Regular inspections and addressing potential leaks can ensure optimal performance, maintaining safety and reliability on the road.

Applications of Steering Cylinders in Vehicles

Steering cylinders play a vital role in vehicle steering systems. They are hydraulic components that assist in converting the driver’s input into movement. This device allows the wheels to turn smoothly, enhancing vehicle control. In modern vehicles, steering cylinders are essential for safety and maneuverability.

In trucks and buses, these cylinders are crucial. They help with heavy steering loads, making it easier to navigate tight corners. In smaller vehicles, steering cylinders offer quick response times. Drivers appreciate the precision they provide. However, these components can wear out over time. Regular maintenance is necessary to ensure safety and effectiveness.

The importance of steering cylinders extends beyond ease of driving. They contribute significantly to overall vehicle performance. A malfunctioning steering cylinder can lead to steering instability. It’s crucial to monitor these systems. Understanding their role can lead to safer and more efficient driving experiences. Keep an eye on any steering issues; it can prevent larger problems down the road.

Applications of Steering Cylinders in Vehicles

Maintenance and Troubleshooting Tips for Steering Cylinders

Steering cylinders play a crucial role in precise vehicle handling. They help control the steering mechanism by managing hydraulic pressure. However, like any system, they can experience issues. Regular maintenance can prevent many common problems.

Check for leaks regularly. A small leak can lead to significant hydraulic fluid loss over time. Inspect connections and hoses for cracks or loose fittings. These small details can save you from more costly repairs later on. If the steering feels stiff or unresponsive, it may indicate a problem. An immediate check can help identify the issue before it worsens.

Cleaning the cylinder regularly is essential. Dirt and debris can affect its performance. Use a damp cloth to wipe around the cylinder, ensuring no foreign substances get inside. Remember that signs of wear are not always obvious. If you notice unusual noises or vibrations, don’t ignore them. Addressing these issues promptly can extend the life of your steering cylinder.